These crucial and well-desired subjects are exactly whatIndustrial NetDevOpsis trying to solve. And DevNet has the tools and learning resources to help you start with that journey right away:

Industrial NetDevOps brings the culture, tools, technical methods and best practices from DevOps to Industrial Networks.

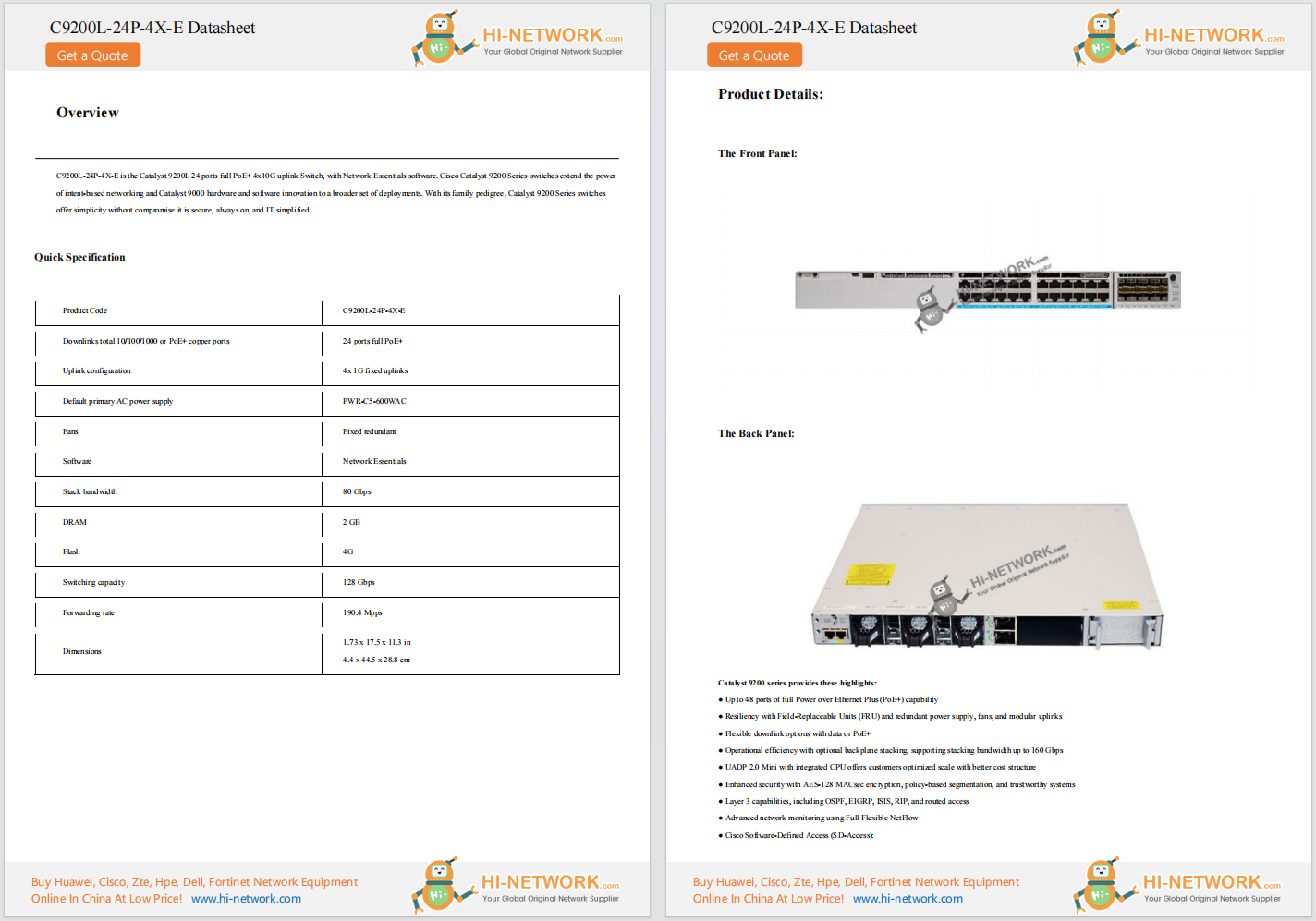

Instead of using SNMP and CLI, you configure, manage and monitor industrial network devices via standardized network device APIs and software automation tools. Industrial NetDevOps workflows use Open Source, standards and Python scripts alongside commercial devices and tools to deliver fast-responsive and secure industrial networks. NetDevOps was already introduced by Hank Preston in 2017.

DevOpsis a set of practices that combines software development (Dev) and IT operations (Ops). Similar to DevOps, in the industrial space are industrial operations professionals who understand and control the equipment (OT/Dev), but need support from their IT colleagues to make OT-data meaningful, OT-devices accessible and better aligned with other business systems (IT/Ops).

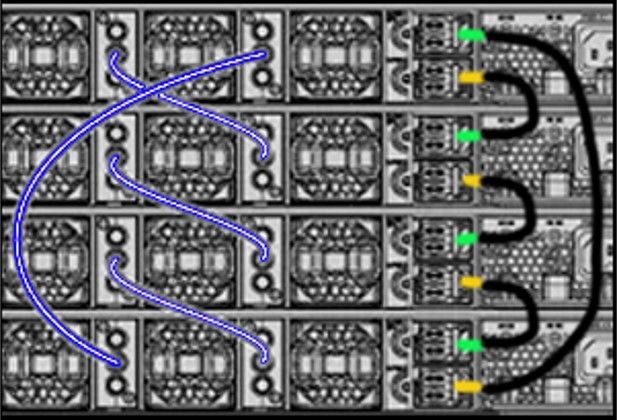

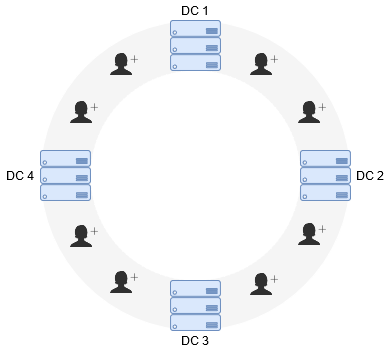

The vision of Industrial NetDevOps is taking the full advantage of both teams by working together: Creating a single source of truth for network configurations (e.g. with Git), making small but well tested changes to the network, deploy configuration changes though APIs, use automation to save time and costs, enable automated IT network services for operations professionals, get real-time health data of your network and OT devices and many more.

Operations leaders recognize that operational data they use to support real-time decision making could create additional value for the company. The vision of a fully connected factory is real, the transformation is happening right now. Therefore, the industrial network needs to be as responsive, agile and secure as it has ever been.

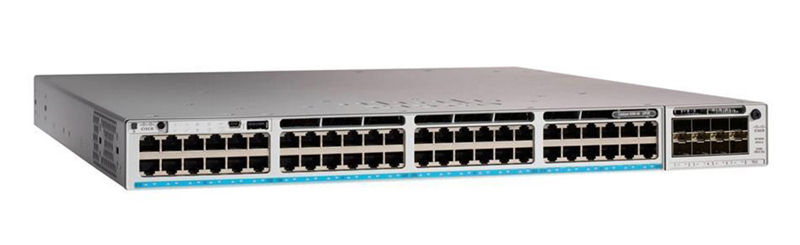

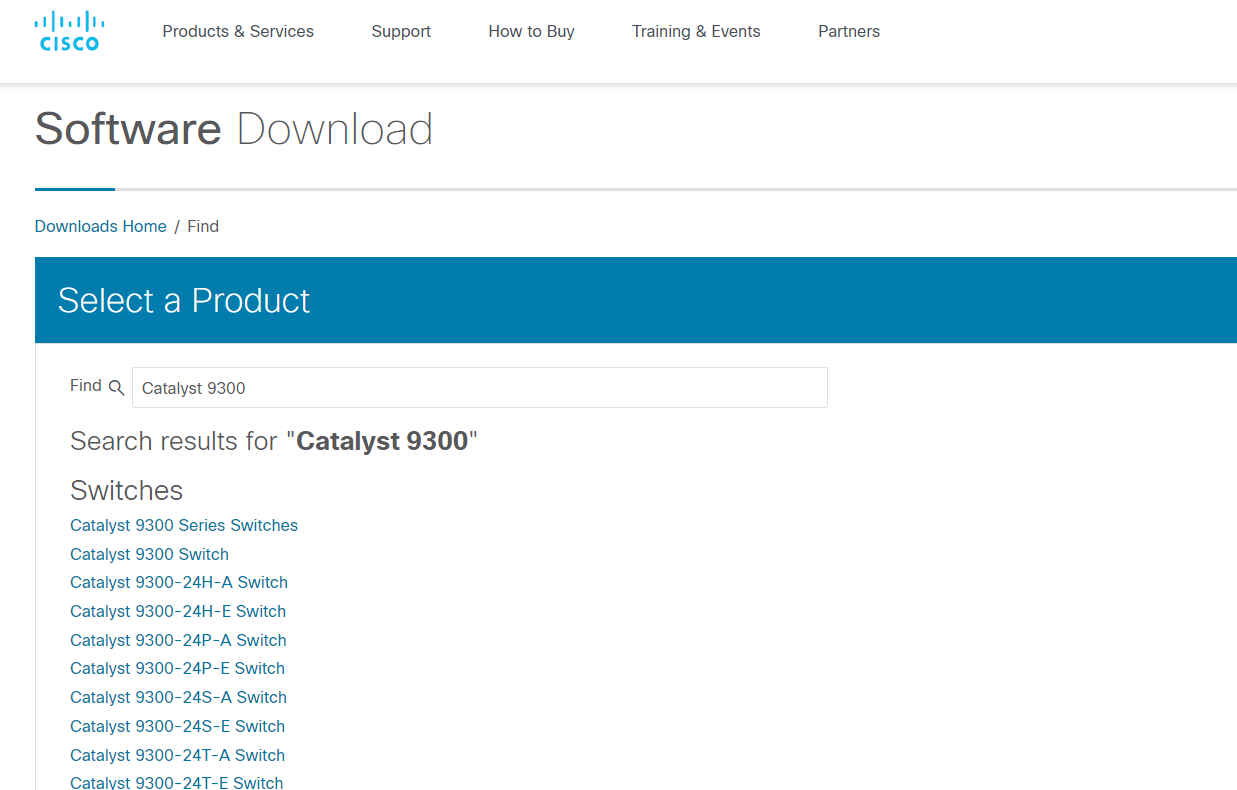

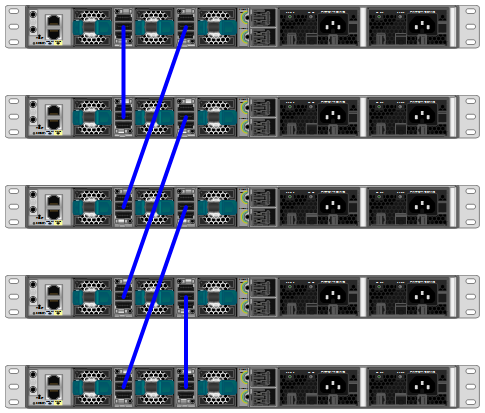

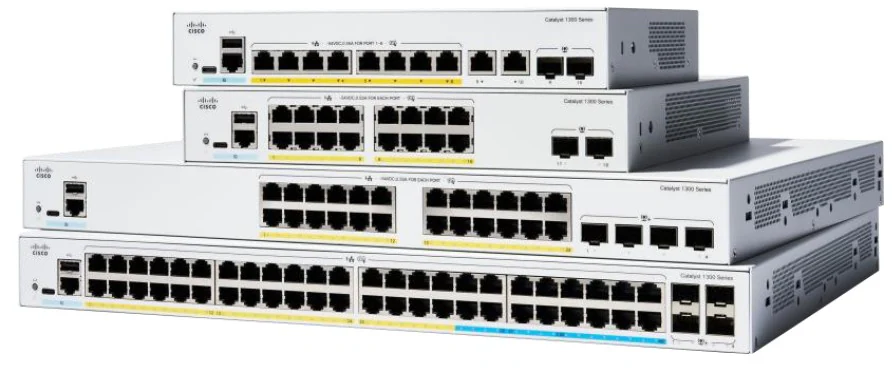

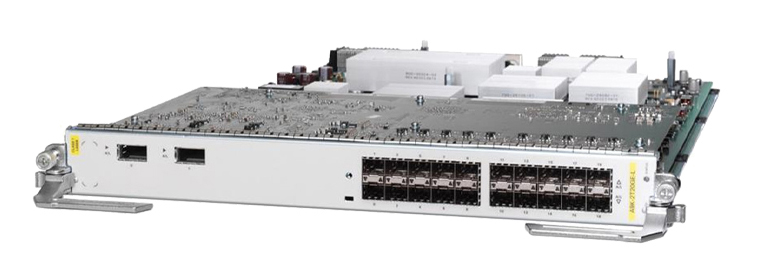

Cisco realized this movement and is leading it: The industrial switch series IE3x00, the embedded switch ESS3300 and the industrial router IR1101 are running IOS XE (same as on the Catalyst 9000 Series) which enables model-driven programmability with open APIs and data models such as NETCONF/RESTCONF & YANG. Also, the Cisco Catalyst 9800 Series Wireless Controller supports model-driven programmability along with traditional APIs.

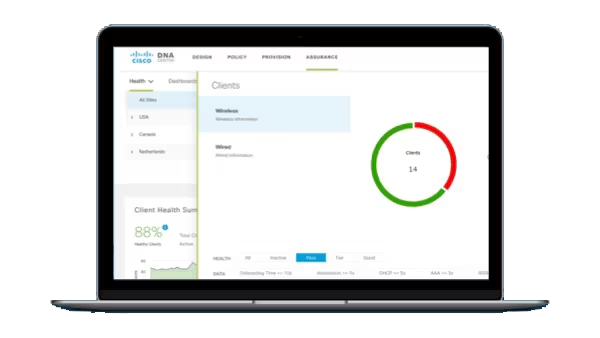

Furthermore, the network controller and orchestration software Cisco DNA Center supports an extensive REST-API as well as the industrial security software Cisco Cyber Vision. As you can see, Cisco

Etiquetas calientes:

Cisco DevNet

netdevops

IoT Development

Etiquetas calientes:

Cisco DevNet

netdevops

IoT Development