Co-Authored by Joe Kann, Rockwell Automation

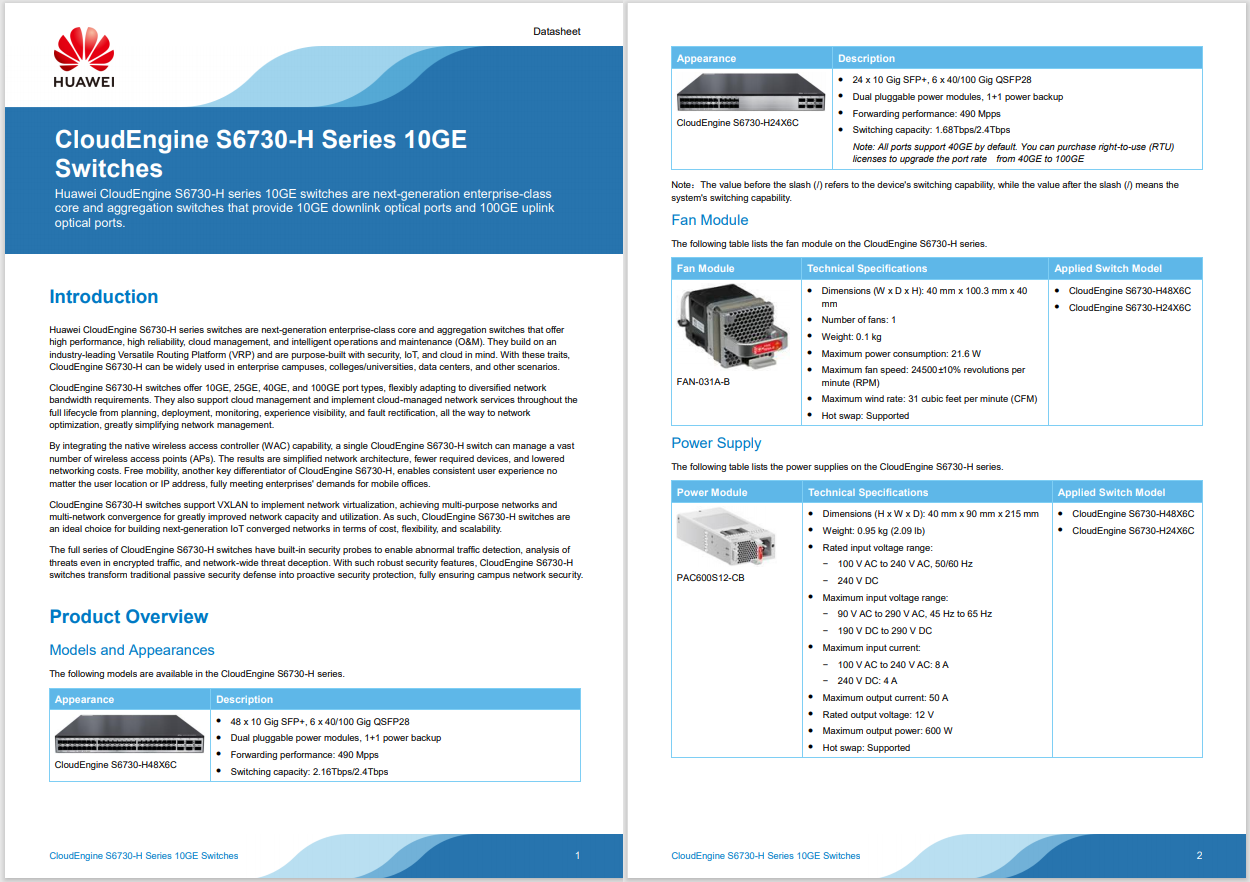

Innovative manufacturers are realizing the value of the Industrial Internet of Things (IIoT) by mapping out use cases that translate to immediate business value and outcomes. In fact, manufacturing represents the largest global industry with "digital value at stake" in the private sector, an estimated$6.1 trillion, according to a recent analysis done by Cisco. The alliance between our two companies, Rockwell Automation and Cisco, has really been focused on helping customers on their digital journey to transform their manufacturing operations to capture this value and business outcomes.

Digital manufacturing has already transformed operations at Daimler Trucks North America (DTNA). For DTNA, success isn't just about controlling costs. It's about building an agile company that can deliver exactly what the market demands-today and tomorrow.

DTNA, a Daimler company, is the largest heavy duty truck manufacturer in North America and a leading producer of medium-duty trucks and specialized commercial vehicles, including iconic brands such as Freightliner, Western Star, Freightliner Custom Chassis, Thomas Built, and Detroit. The Portland manufacturing facility builds a variety of commercial vehicles, including four different models of Western Star trucks. Each model is customized for specific requirements and tailored to every customer's needs, which isn't easy in a mass production environment.

https://youtu.be/zi_Y1zYnALg

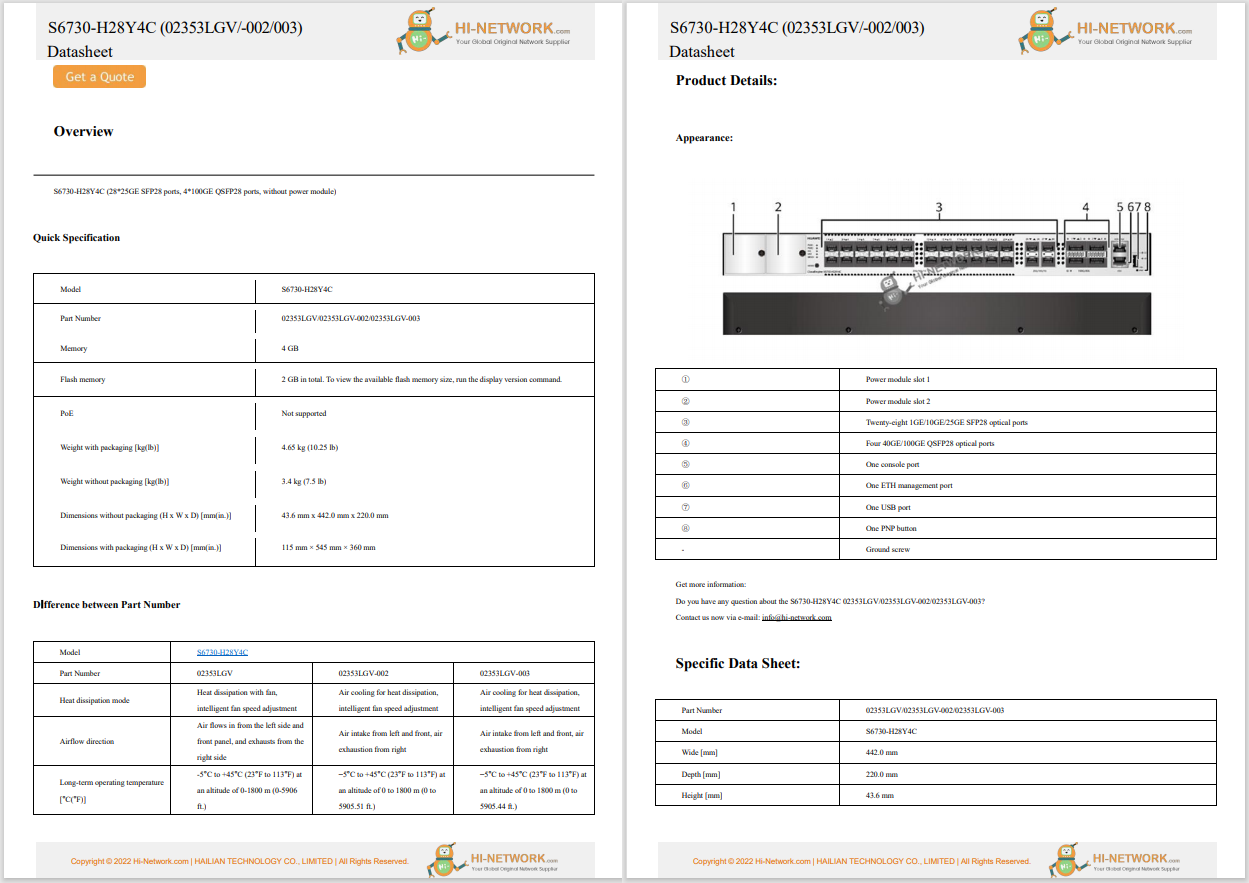

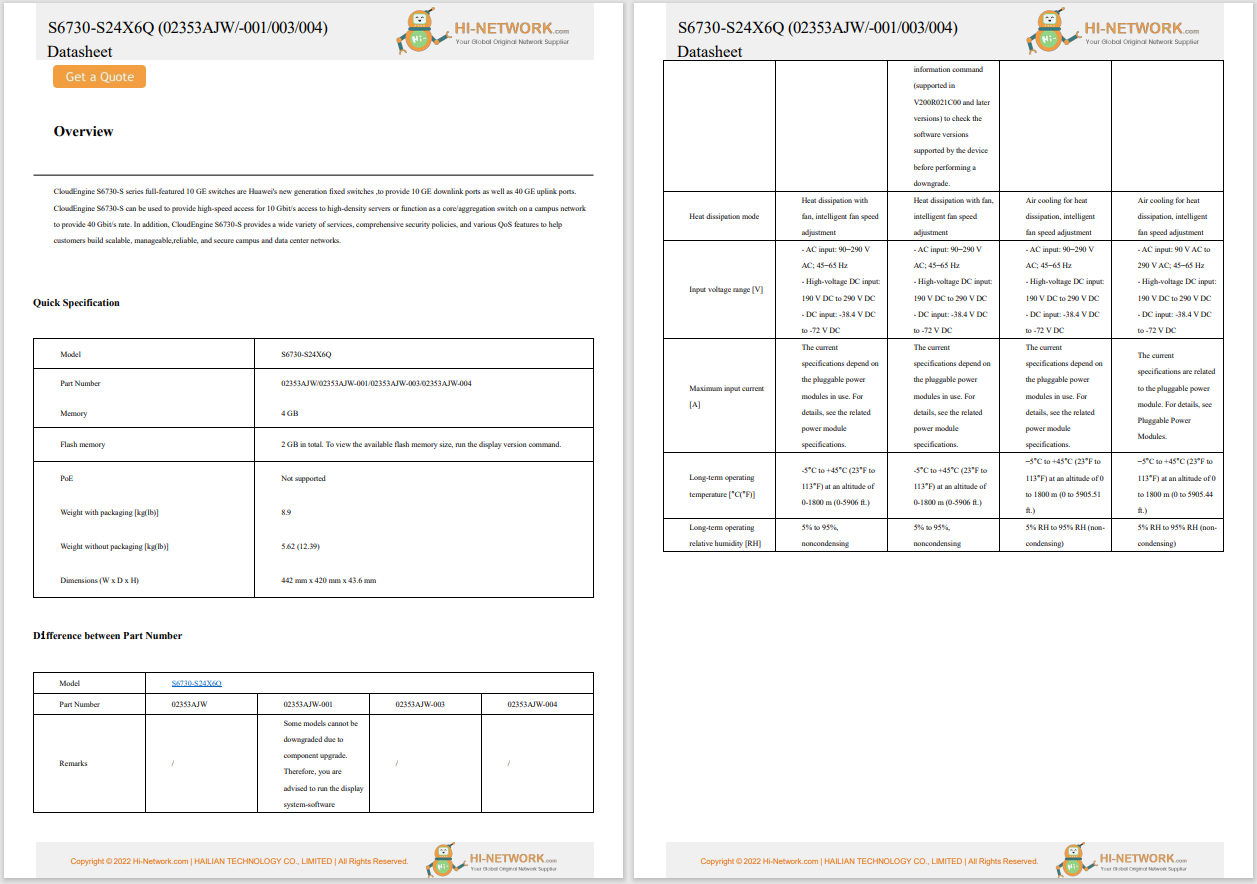

DTNA decided that it needed to upgrade the network in its Western Star production facility to better coordinate truck customizations and support flexible and efficient operations, both now and in the future. The company also wanted a new network to serve as a foundation for innovative production applications and automation systems, including RFID for asset tracking.

Paul Erdy, Plant Manager of Western Star said:

"We coordinate all of the parts coming together on a single truck. Each truck that comes down the line is like a snowflake-no two are alike. We offer different configurations of wheel bases, axles, colors, air cleaners, and other options, and we customize each truck to meet the needs of the customer."

Improving Production Visibility in the Factory

DTNA turned to our two companies as strategic partners in this effort, designing and deploying a new network based on our jointly developed Converged Plantwide Ethernet (CPwE) validated design guide. Secure and seamless Wi-Fi connectivity across the plant was critical since team leaders and supervisors needed to communicate reliably over wireless phones to manage production on the floor. After installing the new network, DTNA is able to use wireless devices, such as iPads, to confirm the truck configurations, check part supply levels, retrieve partsfromthe warehouse, and confirm truck status in real time.

A Secure, Award-winning Plant-to-Business Network

By combining IT and automation networks into one secure, manageable, and converged environment, DTNA managers have gained real-time visibility across production and operations. Data is transmitted securely to managers, helping them make better, faster decisions that keep plants running efficiently. Software-defined networking (SDN) also supports remote troubleshooting to minimize downtime when equipment needs maintenance or repair. The architecture scales to any size or configuration, allowing DTNA to use the Western Star factory as a template, which it is rolling out across other factories including North Carolina and Mexico. The deployment of this project was recently awarded a winner of a 2016 Manufacturing Leadership Award in the Enterprise Technology Leadership Category for its Portland Truck Manufacturing Plant Project.

Business Results Translate to Value

In the competitive trucking business, meeting customer expectations in value, quality, and delivery are key.

Dieter Haban, CIO of DTNA, explains how to achieve this:

"We produce and collect a massive amount of data to understand where we are during the assembly of the truck. Now we can provide dashboard information to management, stay informed about any parts shortages, and know the status of the vehicle in real time, any time."

We look forward to continuing to partner with DTNA for many years to come as they continue on their journey to become a fully digital manufacturer. For more details on the keys to success for DTNA's network upgrade, read Chet Namboodri's blog. The full case study is available here:

Digital Manufacturing Powers a Better Way to Build Trucks from Connected Futures

Etiquetas calientes:

Transformación Digital

automation

Cisco Industrial IoT (IIoT)

Digital Manufacturing

CPwE

Daimler Trucks

Daimler

Factory

Freightliner

Etiquetas calientes:

Transformación Digital

automation

Cisco Industrial IoT (IIoT)

Digital Manufacturing

CPwE

Daimler Trucks

Daimler

Factory

Freightliner