Realizing the full potential of industrial digitization requires extensive connectivity of operations assets wherever they might be -at busy city intersections, inside utility substations, in rail and subway stations, along extreme temperatures and high-vibration production lines, within wind or solar farms, in mines and in oilfields. In these kinds of harsh environments, organizations need to deploy, secure, and maintain a wide range of connected devices. Full connectivity is the starting point and needs a network that is scalable, resilient, secure, and incorporates proven IT practices to keep the network performing up to expectations.

In January last year, Cisco launched the first two products in the Cisco Catalyst IE9300 Rugged Series Switches portfolio. These switches are closely related to the widely adopted Cisco Catalyst 9000 family with the same hardware ASICs, the same IOS XE operating system, and offer the same level of network automation, assurance, and policy enforcement by Cisco Catalyst Center (previously known as Cisco DNA Center). This year, we are extending that portfolio with one of the industry's most innovative and comprehensive product sets.

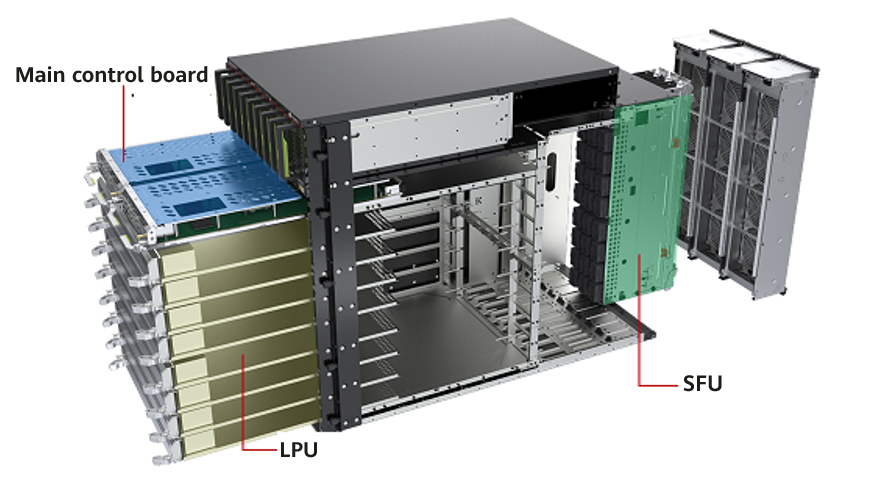

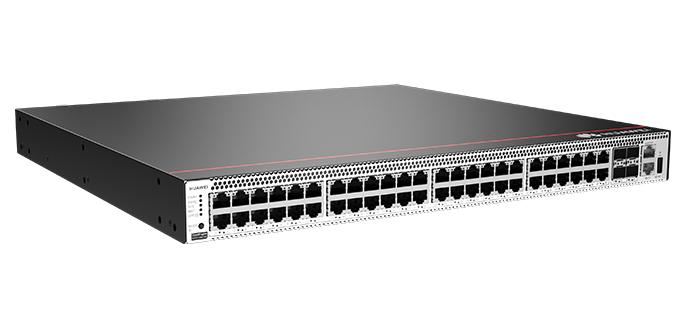

Figure 1: Catalyst IE9300 Rugged Series all-fiber models

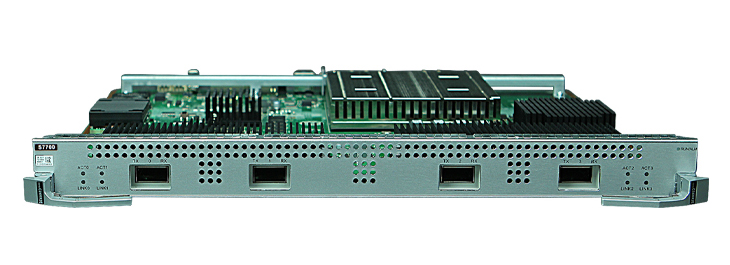

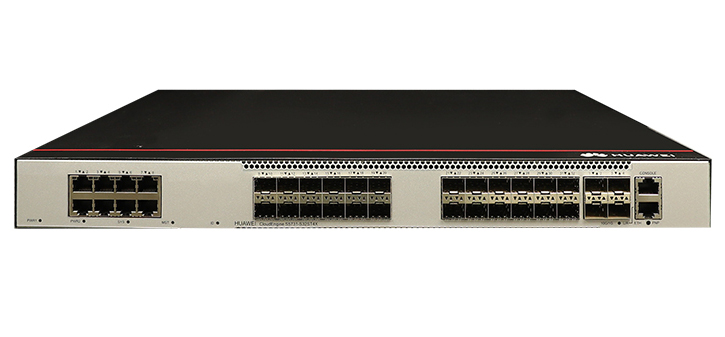

The new all-fiber and all-copper models of these rackmount, Layer 3 switches deliver the same security, scalability, and automation that customers have come to expect from our Catalyst 9000 enterprise-grade rackmount switches. But the Catalyst IE9300 switches are ruggedized for industrial environments -unlocking new opportunities to bring enterprise-grade networking to industrial networks.

Specific features make these multifunction switches especially powerful and versatile. For example, the latest models offer higher Power over Ethernet (PoE) wattage and high PoE budget (up to 720W). That means organizations can connect more -and higher-power, higher-bandwidth -endpoints, including Wi-Fi 6/6E access points, 4K UHD and PTZ cameras, digital signage, and even thin clients and user laptops, to name a few.

These models also provide higher bandwidth -up to 2.5GE downlinks and 10GE uplinks -for high-bandwidth endpoints and to enable data to be backhauled from many access switches in field deployments such as road intersections, railroads, and manufacturing environments. For utilities, the products' high-density fiber ports and IEC 61850 compliance make them ideal for substation automation. Across industry sectors and use cases, Software-Defined Access makes it easier to interface industrial networks with enterprise networks. They also unlock the benefits of Cisco Cyber Vision and Endpoint Analytics to enhance visibility and security throughout industrial networks.

Figure 2: Catalyst IE9300 Rugged Series all-copper models

The IE9300 family is built to withstand extreme temperatures and is hardened for vibration, shock and surge, and electrical noise. These switches offer extended durability thanks to no moving parts and their fanless, convection-cooled design. And they comply with specifications for several industries -from Intelligent Transport Systems (ITS) to utility substation environments.

To put it more conversationally, you can think of the Catalyst IE9300 Rugged Series as the Layer 3 switches that you can use for (almost) everything and (nearly) everywhere!

One of the best ways to illustrate the potential of these new products is to describe some of the use cases they make possible:

Etiquetas calientes:

Cisco Industrial IoT (IIoT)

Cisco DNA Center (en inglés)

Cisco Secure Industrial Networking

Wi-Fi 6

Cisco Industrial Ethernet Switches

Cisco Catalyst Center

Cisco Catalyst IE9300 Rugged Series Switches

Etiquetas calientes:

Cisco Industrial IoT (IIoT)

Cisco DNA Center (en inglés)

Cisco Secure Industrial Networking

Wi-Fi 6

Cisco Industrial Ethernet Switches

Cisco Catalyst Center

Cisco Catalyst IE9300 Rugged Series Switches